In the blazing heat of jet engines running at 1,200°C, a temperature where usual metals would melt and break disastrously, only one material is left unhurt: Inconel. The superalloy is the main material in modern aerospace, energy, and chemical processing industries which has become the driver of such technological breakthroughs that were just dreaming a few decades ago.

This very detailed guide is going to be your comprehensive resource to learn all about Inconel, from its very basics composition up to the most sophisticated applications, thus making you able to comprehend the reasons why this premium metal alloy enjoys so much respect and high prices in the globe’s most important industries.

Understanding Inconel: The Basics

What is Inconel Metal?

The better part of the Inconel brand of superalloys from the austenitic nickel-chromium family are designed for applications that go beyond the capability of the usual materials. A company called International Nickel made Inconel in the 1940s to produce one of the most successful superalloy families in history.

Key Features of Inconel Metal:

- Stands up to extreme heat

- Tough in harsh environments

- Stays strong when hot

- Easy to work with

- Non-magnetic

Unlike ordinary steel or aluminum alloys, Inconel belongs to a specialized class called superalloys—metals engineered to maintain structural integrity at temperatures above 1,000°F (540°C). The Inconel family includes over a dozen different grades, each optimized for specific applications from aerospace to marine environments.

What is Inconel Made Of?

Inconel’s composition is the reason behind its outstanding performance in high temperature issues. Every element of the alloy has a very specific mission in accomplishing the remarkable properties of the alloy.

Primary Components:

- Nickel (50-80%): Gives austenitic structure, ductility, and corrosion resistance

- Chromium (15-25%): Makes a protective oxide film for oxidation resistance

- Iron (5-20%): Strengthens and regulates thermal expansion

Secondary Alloying Elements:

- Molybdenum (2-10%): Improves corrosion resistance against acids and chlorides

- Niobium: Allows the process of precipitation hardening in the grades such as Inconel 718

- Titanium & Aluminum: Are the sources of gamma-prime precipitates for the creep resistance

| Element | Inconel 600 | Inconel 625 | Inconel 718 | Inconel X-750 |

|---|---|---|---|---|

| Nickel (Ni) | 72.0 min | 58.0 min | 50.0–55.0 | 70.0 min |

| Chromium (Cr) | 14.0–17.0 | 20.0–23.0 | 17.0–21.0 | 14.0–17.0 |

| Iron (Fe) | 6.0–10.0 | ≤5.0 | Balance | 5.0–9.0 |

| Molybdenum (Mo) | — | 8.0–10.0 | 2.8–3.3 | 0.5 max |

| Niobium (Nb) | — | 3.15–4.15 | 4.75–5.5 + Ta | 0.7–1.2 |

| Cobalt (Co) | ≤1.0 | ≤1.0 | ≤1.0 | ≤1.0 |

| Titanium (Ti) | ≤0.60 | ≤0.40 | 0.65–1.15 | 2.25–2.75 |

| Aluminum (Al) | ≤0.35 | ≤0.40 | 0.2–0.8 | 0.4–1.0 |

| Carbon (C) | ≤0.15 | ≤0.10 | ≤0.08 | ≤0.08 |

| Manganese (Mn) | ≤1.0 | ≤0.5 | ≤0.35 | ≤1.0 |

| Silicon (Si) | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 |

| Sulfur (S) | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 |

| Copper (Cu) | ≤0.5 | ≤0.4 | ≤0.3 | ≤0.5 |

| Boron (B) | — | — | ≤0.006 | — |

Note: Values are approximate and may vary slightly depending on product form and supplier specifications.

The precise composition represents decades of metallurgical research, with each element’s percentage optimized through extensive testing to achieve specific performance targets.

Popular Inconel Grades and Their Specifications

What is Inconel 718?

Inconel 718 is the most broadly utilized nickel-chromium-based superalloy that can be precipitation-hardened for mission-critical applications throughout the world, representing over 35% of all the superalloys produced. The material has been extensively known because of the remarkable performance that it has shown under stringent conditions for many years.

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 50–55% |

| Chromium (Cr) | 17–21% |

| Niobium + Tantalum (Nb + Ta) | 4.75–5.5% |

| Molybdenum (Mo) | 2.8–3.3% |

| Iron (Fe) | Balance |

| Property | Value |

|---|---|

| Tensile Strength | Up to 1,400 MPa (200 ksi) |

| Operating Temperature | Up to 700°C (1,290°F) |

| Fatigue Resistance | Excellent |

| Hardening Mechanism | Precipitation hardening |

Inconel 718 is unique because of its precipitation-hardening feature which is done by a regulated heat treatment that generates small precipitates in the crystal structure thereby significantly improving the strength of the material while maintaining its ductility.

Common Applications:

- Gas turbine engines (aircraft and industrial)

- Rocket engines and aerospace components

- Nuclear reactor parts

- Oil and gas downhole tools

- Cryogenic storage tanks

What is Inconel 625?

Inconel 625 is the leader of corrosion-resistant superalloys and it is specially made for chemical environments that are extremely aggressive and even other premium alloys cannot handle.

Composition of Inconel 625:

- Nickel: 58% minimum

- Chromium: 20-23%

- Molybdenum: 8-10%

- Niobium: 3.15-4.15%

Superior Properties:

- Exceptional seawater corrosion resistance

- Outstanding performance in acidic environments

- Continuous service up to 980°C (1,800°F)

- Excellent weldability and fabricability

| Element | Symbol | % Composition |

|---|---|---|

| Nickel | Ni | 58 |

| Chromium | Cr | 21.5 |

| Molybdenum | Mo | 9 |

| Iron | Fe | 5 |

| Copper | Cu | 0 |

| Manganese | Mn | 0.5 |

| Titanium | Ti | 0.4 |

| Silicon | Si | 0.5 |

| Aluminum | Al | 0 |

| Sulphur | S | 0.01 |

| Carbon | C | 0.1 |

| Cobalt | Co | 1 |

| Niobium + Tantalum | Nb + Ta | 3.65 |

| Silver | Ag | 0.5 |

| Phosphorus | P | 0.01 |

| Tungsten | W | 0 |

| Vanadium | V | 0 |

| Nitrogen | N | 0 |

Inconel 625, with its high molybdenum content, is not only very resistant to pitting, crevice corrosion, and stress corrosion cracking in chloride environments, but it also has such properties that make it a perfect choice for chemical processing and marine industries.

Primary Applications:

- Seawater systems and marine hardware

- Chemical processing equipment

- Nuclear reactor components

- Pollution control systems

- Offshore oil platform components

What is Inconel Used For? Key Applications and Industries

Aerospace and Aviation:

The aerospace industry represents Inconel’s most demanding applications, where component failure could result in catastrophic consequences. Modern aircraft engines operate under extreme conditions that push materials to their absolute limits.

Critical Aerospace Applications:

- Turbine Discs: Carry high centrifugal loads at high temperature

- Turbine Blades: Keep correct aerodynamic shapes even under very hot conditions

- Combustion Chambers: The heat from the combustion process is directly applied

- Exhaust Systems: Operation under high temperature for a long time

A modern commercial aircraft engine may contain over 40% Inconel 718 by weight, demonstrating the alloy’s critical importance in advanced propulsion systems.

Oil and Gas Industry

The oil and gas sector presents challenging environments combining high temperatures, extreme pressures, and highly corrosive fluids. Inconel has become essential for equipment operating in these harsh conditions.

Key Applications:

- Downhole Tools: Deep wells reaching 200°C (400°F) and 1,000+ bar pressure

- Wellhead Equipment: Critical pressure-containing applications

- Offshore Platforms: Seawater exposure combined with hydrocarbon processing

- Subsea Equipment: Underwater operation for years without maintenance

Chemical Processing

Chemical plants demand materials that withstand aggressive chemicals at elevated temperatures and pressures. Inconel provides solutions where conventional materials fail.

Applications Include:

- Heat exchangers handling corrosive process streams

- Reaction vessels and pressure reactors

- Piping systems for aggressive chemic

What Makes Inconel So Special? Unique Properties and Advantages

Exceptional High-Temperature Performance

The main property determining the identity of Inconel is its amazing capability to hold structural strength at very high temperatures that would cause other materials to go into a catastrophic failure.

Temperature Capabilities:

- Inconel 600: Up to 1,177°C (2,150°F)

- Inconel 625: Up to 980°C (1,800°F)

- Inconel 718: Up to 700°C (1,290°F)

High-Temperature Advantages:

- Throughout the whole temperature range, the austenitic crystal structure is stable

- The oxidation resistance of self-healing

- Very good creep resistance

- The mechanical properties at the elevated temperature were retained

Outstanding Corrosion Resistance

Corrosion resistance of Inconnelr is not only limited to resisting the oxidation but also the protection it provides against such parts of chemical world that are aggressive.

Corrosion Resistance Features:

- Very good pitting and crevice corrosion resistance

- Great performance in acidic environments

- The resistance of stress corrosion cracking is at the highest level

- The chemical spectrum is very wide thus compatibility

Inconel vs. Other Materials

Situations where it is wise to pick Inconel would be after looking at the side and comparing its features with those of another materials.

Inconel vs. Stainless Steel:

- High-temperature capability

- Higher initial cost but usually lower operating costs over time

When to choose Inconel:

- Temperatures that are above 540°C (1,000°F)

- Highly corrosive environments

- Applications that are very important where if they fail the consequences will be very serious

- Places that are far away

Working with Inconel: Fabrication and Welding Considerations

Is Inconel Difficult to Weld?

It presents unique welding challenges but can be successfully welded using proper techniques and procedures.

Welding Challenges:

- Work Hardening: Rapid hardening during welding process

- Heat Input Control: Requires precise temperature management

- Hot Cracking: Susceptibility to solidification cracking

- Contamination Sensitivity: Must prevent contamination during welding

Successful Welding Solutions:

- Use appropriate filler metals (typically matching composition)

- Control interpass temperature (150°C maximum)

- Employ proper joint preparation and fit-up

- Use inert gas shielding (argon or helium)

- Post-weld heat treatment when required

Recommended Welding Processes:

- Gas Tungsten Arc Welding (GTAW/TIG)

- Gas Metal Arc Welding (GMAW/MIG)

- Electron Beam Welding for critical applications

- Laser welding for precision work

Machining and Fabrication

Working with this material requires specialized techniques due to its work-hardening characteristics and abrasive nature.

Machining Considerations:

- Use sharp, properly designed cutting tools

- Maintain consistent feed rates to prevent work hardening

- Employ adequate coolant/lubrication

- Consider ceramic or carbide tooling for extended tool life

Selecting the Right Inconel Grade for Your Application

Application-Based Selection Guide

Choosing the appropriate Inconel grade requires careful consideration of operating conditions and performance requirements.

Selection Criteria:

- Temperature Requirements: Match grade capability to operating temperature

- Corrosion Environment: Consider specific chemicals and concentrations

- Mechanical Properties: Evaluate strength, fatigue, and creep requirements

- Fabrication Requirements: Consider weldability and formability needs

Grade Selection Matrix:

- High Temperature + Strength: Inconel 718

- Maximum Corrosion Resistance: Inconel 625

- General High-Temperature Service: Inconel 600

- Specialized Applications: Inconel 601, 686, X-750

Choosing a Reliable Inconel Supplier

What to Look for in a Metal Distributor?

Selecting the right Inconel supplier is crucial for ensuring material quality and project success.

Essential Supplier Qualifications:

- Quality Certifications: AS9100, ISO 9001, NADCAP approvals

- Material Traceability: Complete documentation from mill to delivery

- Processing Capabilities: Value-added services like cutting, machining, heat treatment

Key Questions for Suppliers:

- What quality management systems are in place?

- Can you provide complete material traceability?

- What technical support services are available?

- What are typical lead times for different grades and forms?

Conclusion

Inconel is beyond metallurgical engineering, which makes it the only material that can perform well in extremely harsh conditions where ordinary materials can not even survive. Inconel is the material that enables technologies that define the modern world such as jet engine turbine blades and oil well exploration at harsh depths.

Knowing what Inconel is, its categories and characteristics, and how it can be used in different fields opens the eyes of engineers and procurement professionals to smarter decisions on selecting materials. However, the high cost of Inconel may seem to be a major disadvantage at the beginning, but its high efficiency, long service life, and reliability in critical applications often lead to a lower total cost of ownership than traditional alternative options.

If you are choosing materials for aerospace, chemical, or marine systems, Inconel’s unique features such as high-temperature strength, corrosion resistance, and proven reliability will definitely make it the most suitable solution for your toughest problems.

Are you planning your next project with Inconel? Our specialists are at your service for your material specifications, application guidance, and competitive pricing of all Inconel grades.

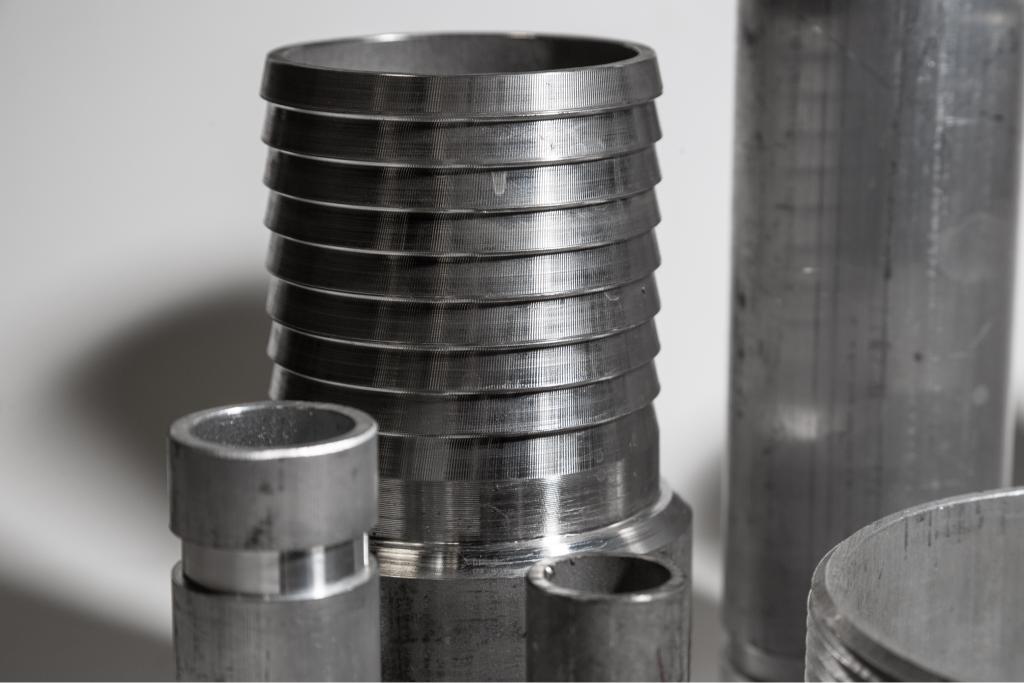

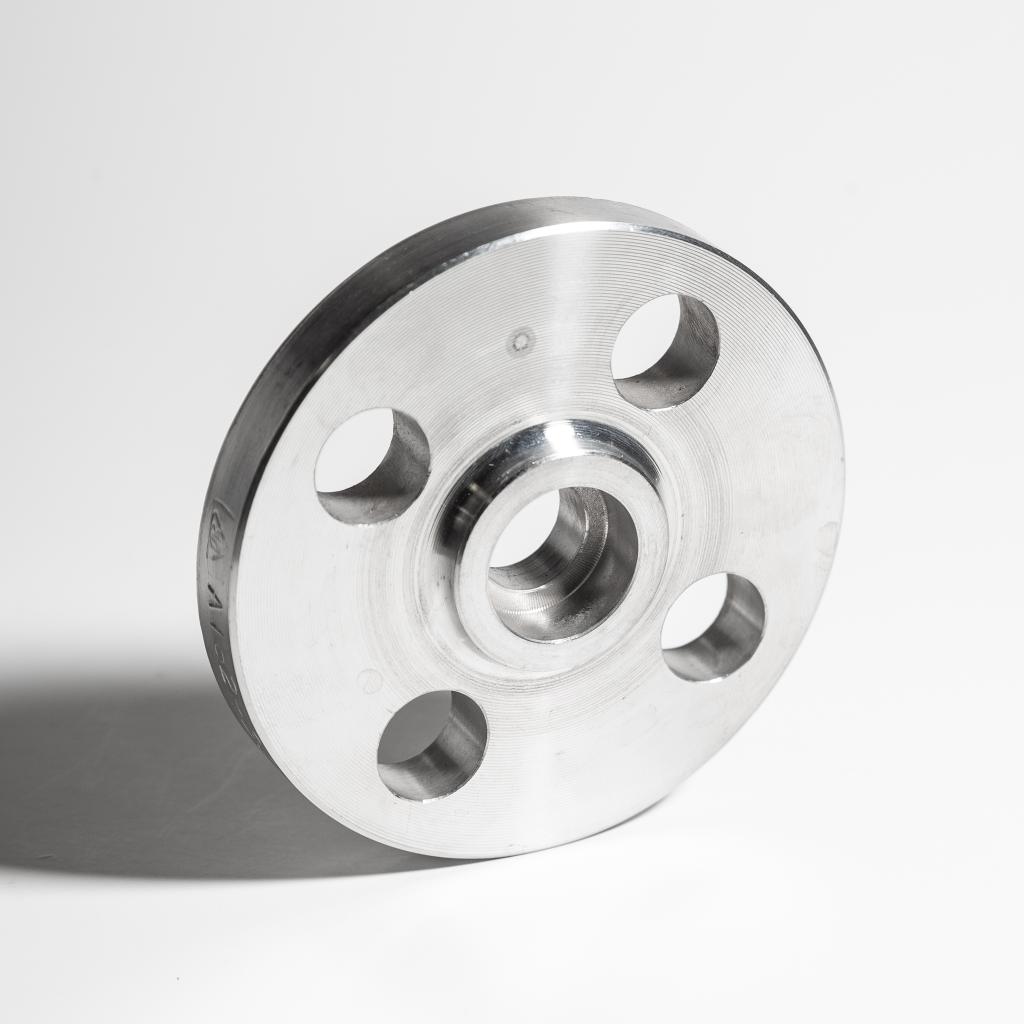

Our Inconel Products

Huron Alloys is a main supplier of high quality Inconel materials, and we are really proud of it. Whether you work in construction, manufacturing, or any other industrial activity, our wide array of Inconel products will certainly cater to your special needs. Moreover, We assure you that all of our products, such as sheets, plates, bars and fittings, are not only solid and rust-proof but also high in performance.

For these reasons, contact Huron Alloys if you require dependable service, top-caliber items, and an unequalled level of understanding on stainless steel. Make the first step in receiving immediate feedback from us so that you can see what kind of assistance we can give you with your ventures.

Similar Products

References

Standards and Specifications

- ASTM B166-19. (2019). Standard Specification for Nickel-Chromium-Iron Alloys (UNS N06600, N06601, N06603, N06690, N06693, N06025, and N06045) and Nickel-Chromium-Cobalt-Molybdenum Alloy (UNS N06617) Rod, Bar, and Wire. ASTM International.

- ASTM B564-19. (2019). Standard Specification for Nickel Alloy Forgings. ASTM International.

- ASTM B622-19. (2019). Standard Specification for Seamless Nickel and Nickel-Cobalt Alloy Pipe and Tube. ASTM International.

- AMS 5662M. (2018). Nickel Alloy, Corrosion and Heat-Resistant, Bars, Forgings, and Rings 52.5Ni – 19Cr – 3.0Mo – 5.1Cb(Nb) – 0.90Ti – 0.50Al – 18Fe Precipitation Hardenable. SAE International.

- AMS 5599K. (2017). Nickel Alloy, Corrosion and Heat-Resistant, Sheet, Strip, and Plate 62Ni – 21.5Cr – 9.0Mo – 3.65Cb(Nb). SAE International.

Technical Publications and Industry Reports

- Donachie, M. J., & Donachie, S. J. (2002). Superalloys: A Technical Guide (2nd ed.). ASM International.

- Reed, R. C. (2006). The Superalloys: Fundamentals and Applications. Cambridge University Press.

- Pollock, T. M., & Tin, S. (2006). Nickel-based superalloys for advanced turbine engines: Chemistry, microstructure and properties. Journal of Propulsion and Power, 22(2), 361-374.

- Special Metals Corporation. (2020). INCONEL® alloy 718 Technical Data Sheet. Publication Number SMC-045.

- Special Metals Corporation. (2019). INCONEL® alloy 625 Technical Data Sheet. Publication Number SMC-063.

- Special Metals Corporation. (2018). INCONEL® alloy 600 Technical Data Sheet. Publication Number SMC-027.

Research Papers and Technical Articles

- Paulonis, D. F., & Schirra, J. J. (2001). Alloy 718 at Pratt & Whitney: Historical perspective and future challenges. In Superalloys 718, 625, 706 and Various Derivatives (pp. 13-23). TMS.

- Oblak, J. M., Paulonis, D. F., & Duvall, D. S. (1974). Coherency strengthening in Ni base alloys hardened by DO22 γ’ precipitates. Metallurgical Transactions, 5(1), 143-153.

- Shankar, V., Rao, K. B. S., & Mannan, S. L. (2001). Microstructure and mechanical properties of Inconel 625 superalloy. Journal of Nuclear Materials, 288(2-3), 222-232.

- Floreen, S., Fuchs, G. E., & Yang, W. J. (1994). The metallurgy of alloy 625. In Superalloys 718, 625, 706 and Various Derivatives (pp. 13-37). TMS.

Manufacturing and Processing References

- Sims, C. T., Stoloff, N. S., & Hagel, W. C. (Eds.). (1987). Superalloys II: High-Temperature Materials for Aerospace and Industrial Power. John Wiley & Sons.

- Campbell, F. C. (2006). Manufacturing Technology for Aerospace Structural Materials. Elsevier.

- Kou, S. (2003). Welding Metallurgy (2nd ed.). John Wiley & Sons.

- ASM International. (1993). Welding, Brazing, and Soldering: ASM Handbook Volume 6. ASM International.

Economic and Market Analysis

- Roskill Information Services. (2023). Nickel: Global Industry, Markets and Outlook to 2033 (20th ed.). Roskill.

- Grand View Research. (2023). Superalloys Market Size, Share & Trends Analysis Report By Product, By Application, By Region, And Segment Forecasts, 2023-2030. Report ID: GVR-2-68038-219-3.

- SMR Steel Market Research. (2023). Global Nickel Alloys Market Report 2023-2028. SMR-NA-2023-145.

Environmental and Safety Standards

- OSHA 29 CFR 1910.1000. (2019). Occupational Safety and Health Standards: Air Contaminants. U.S. Department of Labor.

- EPA 40 CFR Part 261. (2020). Identification and Listing of Hazardous Waste. U.S. Environmental Protection Agency.

Historical and Development References

- Eiselstein, H. L. (1965). Age-hardenable nickel alloy. U.S. Patent No. 3,046,108. Washington, DC: U.S. Patent and Trademark Office.

- International Nickel Company. (1958). Development of INCONEL Alloy X-750. Technical Report INCO-58-142.

- Boesch, W. J., & Slaney, J. S. (1964). Preventing sigma phase embrittlement in nickel base superalloys. Metal Progress, 86(4), 109-111.

Corrosion and Materials Performance

- Fontana, M. G., & Greene, N. D. (1978). Corrosion Engineering (2nd ed.). McGraw-Hill.

- Crook, P. (1994). Corrosion characteristics of nickel-containing alloys in marine environments. Materials Performance, 33(12), 27-34.

- Leonard, A. J. (1969). Development of INCONEL alloy 625. In Proceedings of the Conference on Advanced Materials for Severe Service Applications (pp. 89-103). General Electric Company.

Testing and Quality Control Standards

- ASTM E8/E8M-21. (2021). Standard Test Methods for Tension Testing of Metallic Materials. ASTM International.

- ASTM E21-20. (2020). Standard Test Methods for Elevated Temperature Tension Tests of Metallic Materials. ASTM International.

- ASTM G48-11. (2020). Standard Test Methods for Pitting and Crevice Corrosion Resistance of Stainless Steels and Related Alloys by Use of Ferric Chloride Solution. ASTM International.

Industry Applications and Case Studies

- Aerospace Industries Association. (2022). Materials and Processes Technical Committee Report: Superalloy Applications in Commercial Aviation. AIA-MPT-2022-03.

- API Specification 6A. (2019). Specification for Wellhead and Christmas Tree Equipment (21st ed.). American Petroleum Institute.

- NACE MR0175/ISO 15156. (2020). Petroleum and natural gas industries — Materials for use in H2S-containing environments in oil and gas production. NACE International/ISO.

Recycling and Sustainability

- Reck, B. K., & Graedel, T. E. (2012). Challenges in metal recycling. Science, 337(6095), 690-695.

- Leal Filho, W., et al. (2019). The role of sustainable materials management in circular economy transitions. Resources, Conservation and Recycling, 151, 104447.

Online Resources and Databases

- MatWeb Material Property Data. (2023). INCONEL® Alloy Properties Database. Retrieved from http://www.matweb.com

- ASM Alloy Center Database. (2023). Nickel-Based Superalloys. ASM International. Retrieved from https://www.asminternational.org

Disclaimer

This reference list includes industry standards, technical publications, and research papers current as of June 2025. Standards and specifications are subject to regular updates and revisions. Always consult the most current versions of applicable standards and manufacturer specifications for critical applications.

Note: INCONEL® is a registered trademark of Special Metals Corporation. All trademark rights are acknowledged and respected.